A long-term approach to building

Representatives across the construction industry recently debated at ‘Think longer to build sustainably‘ a RIBA roundtable discussion, the issues connected to building longevity, accurately assessing the cost of embodied carbon over a longer period, and the role of materials that can be re-used at the end of life.

All the contributors agreed on the importance of longer-lived buildings and shared views on a range of associated topics including embodied carbon measurements, comparable data capture, and designing for longevity. Here’s a summary of some of the key points from the discussion:

Instrumental to our everyday lives

The UK ceramic industry’s manufacturing capacity is made up of three sectors. These include ‘Heavy Clay’ construction products predominant in our built environment such as bricks, pavers, tiles and drainage pipes. ‘Whitewares’ which we use every day in our homes and offices such as tableware or giftware, sanitary ware (sinks and baths) and ceramic wall or floor tiles. Thirdly Industrial ceramics and refractories are used in the manufacture of other materials or chemicals, medical artificial joints, with many advanced ceramics used in computers, jet engines, x-ray equipment, radar, water purification, thermal imaging devices and many more.

has been invested by the UK ceramics industry over the last 10 years

reduction in absolute emissions since early 2000’s (UK ceramic sector)

Data from the British Ceramics Confederation June 2023

Measurements

“There is a focus on getting to 2030 and reducing carbon emissions now. But a lot of materials that massively reduce embodied carbon emissions now don’t last that long or will need to be replaced over the length of the building’s life, increasing the embodied carbon emissions dramatically.” Louisa Bowles, partner and sustainability lead at Hawkins\Brown.

“Environmental product declarations often skew the advantages of materials like clay brick because they last so much longer. The brick industry says that clay products last 150+ years. But some brick buildings have lasted for centuries with examples dating back 6000 years. Clay brick has little to no maintenance and therefore zero operational carbon, whilst also being recyclable and reusable. Therefore a 60-year lifespan means you cannot accurately compare material whole-life carbon, cradle-to-cradle against other material choices in our longstanding built environment. We need a longer study period.” Sarah Le Gresley, innovation director, Michelmersh.

“Brick’s durability and manufacturing process make it one of the more environmentally friendly building materials.“

“Brick is one of the most widely used building materials in the UK. Its use dates back to 7000 BC, making it one of the oldest known man-made materials. It is long-lasting, durable, weathers well and, when used in the right context, beautiful. It characterises some of our most treasured historic architecture and contributes to creating a built environment that is perceived as both permanent and safe.”

Six simple rules for more sustainable brick construction, Fran Williams, Architect’s Journal

Design

It is not just the materials that will give buildings a long lifespan. They must also continue to be liveable over a long period.

“We always try to extend the scale, size and volume of apartments. For instance, external balconies are rarely useful, especially above six or seven floors. Instead, they should be incorporated in the volume of the home.” Alex Lifschutz, director, Lifschutz Davidson Sandilands.

“We must design for longevity, with buildings that are adaptable, flexible, not subject to overheating and resistant to fire.” Mike Leonard, CEO, Building Alliance.

So how do we improve things?

One answer is to ensure that valuable data is available, and decisions are made based on knowledge rather than a hunch.

“We encourage the likes of QSs that when measuring for cost, they measure for whole-life carbon also. Without consistent data we won’t make the right choices. The context behind that data is important as well – we need to tell what is and isn’t included.” James Fiske, global director of data and information products, RICS.

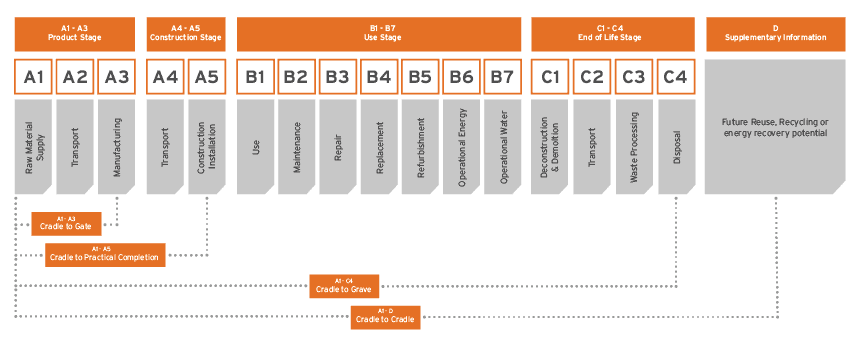

“One of our biggest problems as architects specifying materials is the transparency, quality and accuracy of data. The latest clay brick EPD from the Brick Development Association includes module A-D and is collated from a wide variety of manufacturers’ data, however, we often find that designers are comparing EPDs with bricks that only cover module A1-A3 (product and construction stages). Manufacturers of other materials do not follow the same transparency and therefore the data is not comparable for architects and specifiers.” Sarah Le Gresley, innovation director, Michelmersh.

Module D was introduced in the EN15804+A2 2019 update to cover the net benefits and loads arising from the reuse of products or the recycling or recovery of energy from waste materials resulting from the construction stage, the use stage and the end of life stage.

Our Affiliations

Sustainable Brick (a Michelmersh initiative) highlights resources and information to help specifiers, homebuilders and housebuilders to gather sustainability-related information more easily before making their material choices.