Sector Impact

Buildings are currently responsible for 39% of global energy-related carbon emissions: 28% from operational emissions, from energy needed to heat, cool and power them, and the remaining 11% from materials and construction.

Source: World Green Building Council

The UK ceramics Industry recognises the need to act, playing its part in decarbonisation of building materials and aiding its transition to net zero.

Why brick is a sustainable choice and how it continues to evolve

Innovation

Embracing new Innovation and technologies is key to the transition to net zero. Switching to alternative fuel sources can significantly reduce carbon emissions, as demonstrated in the groundbreaking HyBrick project by Michelmersh. This pioneering initiative showcased a remarkable reduction of 80-84%% switching from natural gas to green hydrogen.

Circularity

Fired product waste is recycled back into the production process or repurposed as aggregates for roads or even tennis courts. Michelmersh incorporates recycled content in products, such as the porcelain white product made from 44% recycled sanitary ware. The industry simultaneously focuses on collecting and reusing products, such as recovering bricks from construction and demolition waste and collecting packaging for re-distribution such as pallets.

Dematerialisation

Dematerialisation drives product development, for example producing products that have less raw material to perform the same function such as thinner bricks which cover the same meter squared footprint of a facade. There is also the ability to use recycled content (reusing materials discarded by other manufacturing processes in different industries) in products to reduce the carbon per unit. Ultimately, thyese products will result in less carbon-intensive production, less transportation, and may result in quicker installation.

Durability

Clay bricks offer excellent acoustic and thermal insulation due to their density. They are highly resilient, capable of withstanding extreme weather conditions, including flooding. Additionally, clay bricks are exceptionally durable, making them suitable for long-lasting, multi-generational use.

Automation

To enhance quality and minimise waste, manufacturers can implement precise product handling and accurate spacing during drying and firing. By utilizing de-hackers and setters, they can ensure there is always careful and efficient movement of products from production to distribution.

Natural Materials

Clay bricks are made from natural raw materials; clay, sand and water, which in turn improve the indoor air quality, thermal mass and acoustic insulation of a space and does not require the application/use of harmful chemicals to maintain the product. After material is extracted, it is shaped and fired to create durable bricks. Manufacturers such as Michelmersh utilise rainwater harvesting methods, using mainly recycled and non-potable water sources throughout the manufacturing process.

Optimised Distribution

Smart traffic routing, efficiency driver training and the adoption of electric or hybrid vehicles, forklifts, and heavy plant machinery are key measures that help reduce scope 1-3 emissions. Michelmersh and other brick manufacturers are committed to decarbonisation strategies, and they are actively exploring hydrogen-powered heavy plant machinery and implementing electrical forklifts at its sites to further lower carbon emissions in material and product transport. Bricks travel on average under 68 miles as an industry, promoting local products for local markets.

Renewable Energy

As sufficient landowners, the brick industry has an ideal opportunity to install renewable energy sources around quarries and factories. Waste heat recycling methods are used in factories to recover heat from kilns and reuse it in dryers, reducing natural gas or electricity usage. Whilst Michelmersh procures the majority of its electricity from renewables it has also undertaken a significant investment programme for the installation of renewables at its factory sites. Manufacturers are also seeking electrification of dryers and kilns which can be powered by renewables and further bringing emissions down.

Reusability

Clay bricks are one of the oldest man-made building products, with examples of their use from thousands of years ago. Clay bricks are well-suited for designing buildings based on circular economy principles, emphasising long service life and adaptability for sustainable construction. Bricks often built with lime mortar, are more likely to be able to be removed carefully during demolition and reused for multiple buildings, maximising their usefulness and retaining their integrity as a durable product that boasts incredible longevity. Brick can be reused and recycled.

Longevity

Clay bricks have a remarkable lifespan of up to 200 years, and there are historical examples of brick structures that are still standing today (thousands of years after they were built). Their longevity reflects their robustness and sustainability, making them a trusted choice for long-lasting and environmentally conscious construction.

Product development and dematerialisation

One of the stages to achieving the roadmap to net zero will include the need for manufacturers to continuously evolve product design and processes.

Michelmersh’s product range includes recycled content products such as the porcelain white smooth which is 44% made from discarded sanitaryware such as baths and sinks. Other products such as its Floren reflections range is a dual face product that can be cut in half (creating two facing products from one unit) for the pre-cast market to save vast amounts of material waste.

Products which promote Biodiversity

FabSpeed’s (a brand from the Michelmersh Group) Bricology range of products are designed to create non-invasive, sustainable, safe havens for an array of species to reduce the risk of predation and the protection of larvae or nests. Britain’s nature loss and decline in native wildlife habitats require innovative products to be produced to enhance biodiversity and support Net Gain principles across our built environment. The Bricology range is the perfect solution that can either be used retrospectively using any manufacturer’s products and prefabricated by the skilled FabSpeed team or for new developments using the versatile core product range from the Michelmersh Group to design-in that biodiverse plan from the start of your project.

Bricology Bird Starling Box

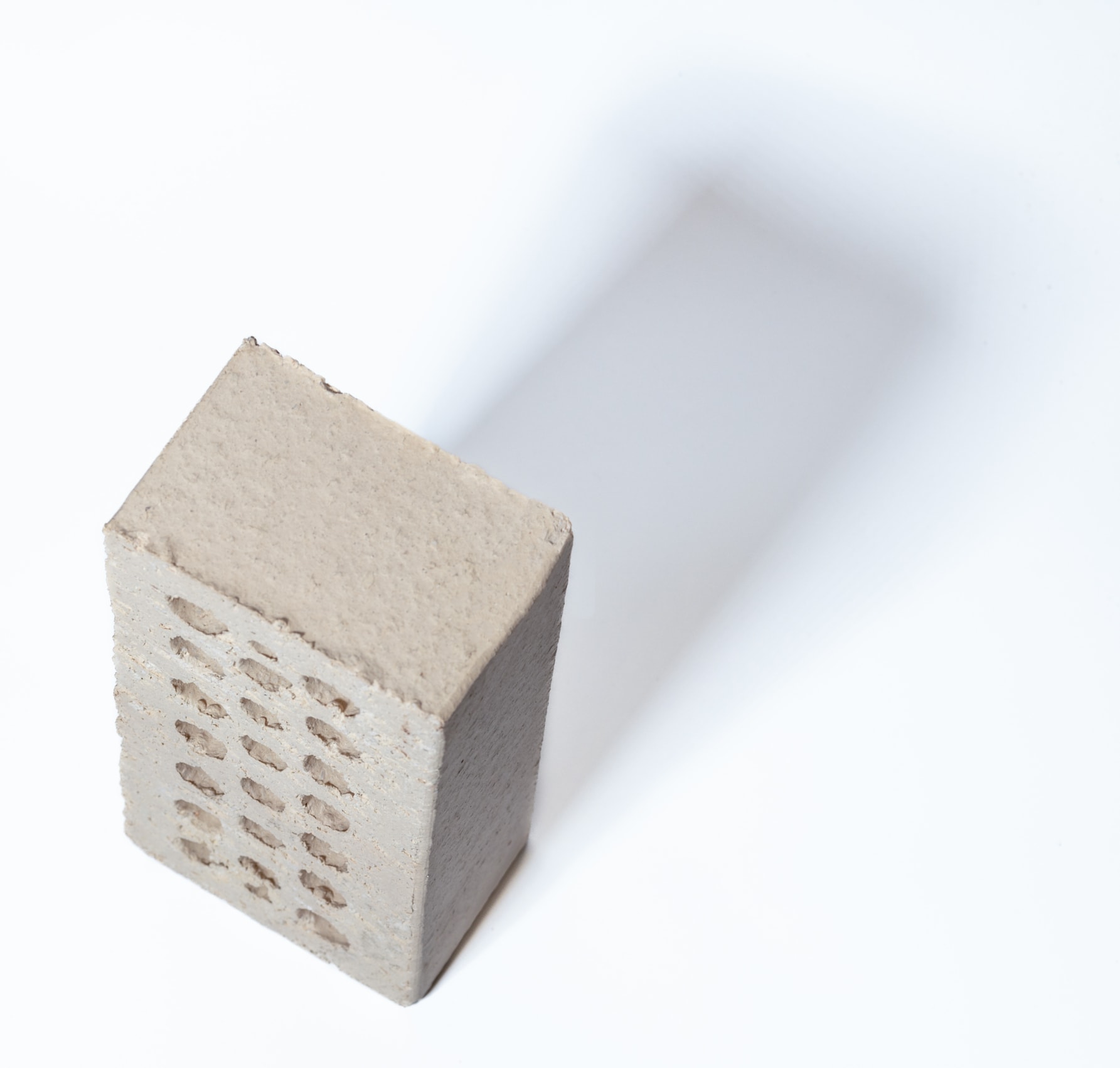

Bricology Bee Brick

Bricology Bird Sparrow Box

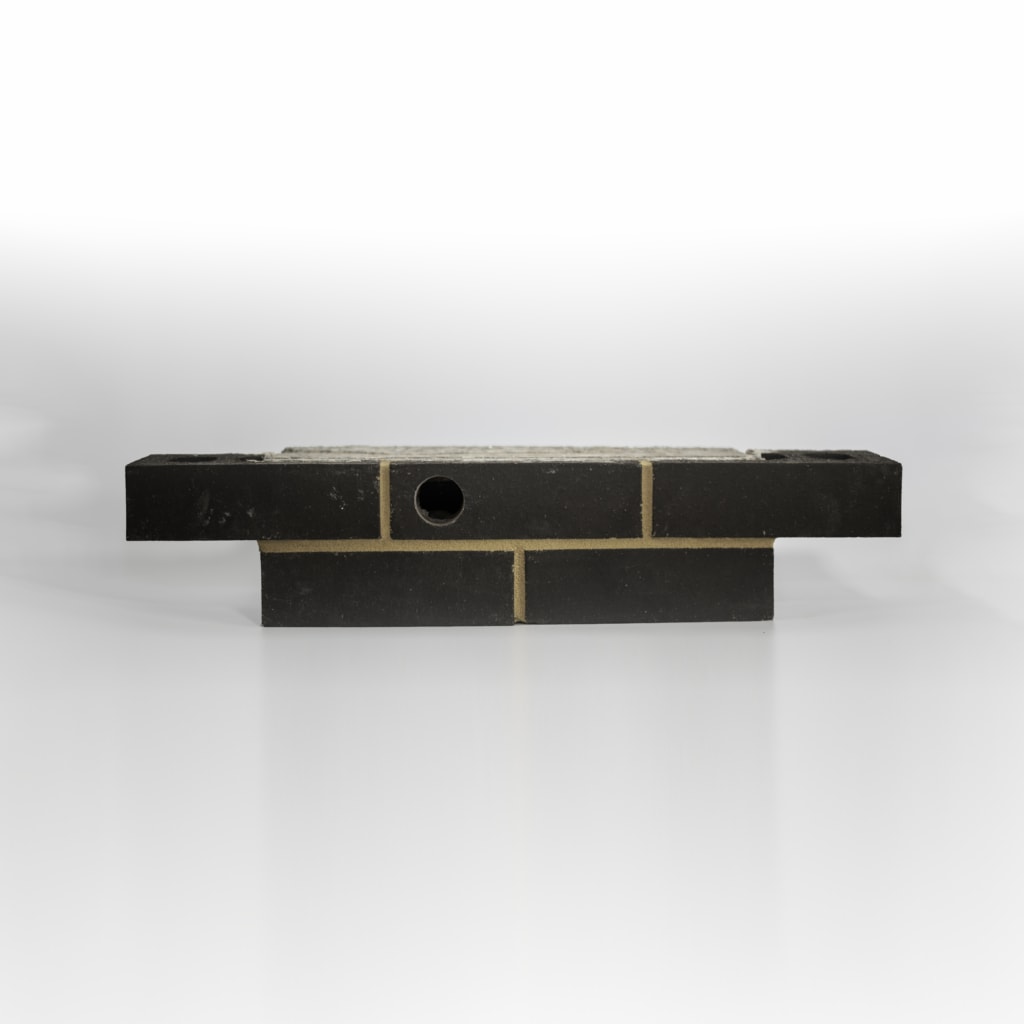

Bricology Bat Box

Reducing energy use and switching to renewables

Manufacturers across the country have already embraced renewable energy procurement across their operations. 91.5% of the Michelmersh Group’s electricity is from renewable sources.

Many manufacturers are also investing where possible in the installation of on-site renewable energy generation methods.

All manufacturers will be motivated to reduce their energy consumption through more efficient production processes. Michelmersh has reduced its energy use (gas and electric) by 15% per kWh per tonne since its 2016 baseline.

Embracing innovation

To make clay brick even more sustainable, several measures can be implemented. First, optimizing the manufacturing process by using advanced kiln technologies and energy-efficient equipment can further reduce energy consumption and greenhouse gas emissions.

Several manufacturers are looking at fuel switching or electrification for significant ways to decarbonise their scope 1 and 2 emissions.

Michelmersh are pioneers in the sector and successfully produced the World’s first 100% hydrogen fired clay bricks which demonstrated a reduction of 80-84% of carbon emissions over the three trials compared to natural gas.

There is also potential through electrolysis powered by renewables for manufacturers to be resilient in their own production of hydrogen, as shown in the animation below.

Michelmersh Group KPI Performance

As of year-end 2022 (Inclusive of Floren) – Calculated from 2016 Baseline.

Read more about Michelmersh’s KPI performance:

Clay bricks epitomize sustainable construction practices by offering a multitude of advantages. With their abundant and naturally sourced clay, energy-efficient manufacturing processes, durability, thermal performance, and recyclability, clay bricks support sustainable building initiatives whilst being produced locally in the UK. Choosing clay bricks for construction projects is a proactive step and whilst manufacturers are looking at new and innovative ways to reduce embodied carbon emissions, specifiers will be confident in its low to zero operational carbon, whilst its in-use benefits and thermal characteristics will enable homeowners to continue conserving energy whilst maintaining its value in their homes for generations to come.

Finally, promoting the recycling and reuse of clay bricks at the end of their life cycle can close the materials loop and minimise waste. By implementing these strategies, clay bricks can continue to further reduce their environmental impact, evolve to embrace more circular principles and continue to be used for future millennia whilst contributing to a sustainable built environment.

DESIGN FOR 200 YEARS, NOT 20.

Responsibly sourced materials

Purchasing sustainably made construction materials, such as clay brick, offers numerous advantages – most importantly, it demonstrates a commitment to designing a built environment that will last for generations, reduce operational building energy consumption and has been responsibly produced. Clay bricks are known for their durability and longevity, whilst also contributing to a healthier indoor environment, aligned with regulatory compliance and certifications whilst ensuring responsible industry practices. Additionally, there is a wide variety of aesthetical choices covering colour and texture produced locally across the UK.

To ensure you choose products made by a responsible brick manufacturer, visit the Brick Development Association’s Brickmakers Quality Charter to see who is certified. Michelmersh was the first manufacturer to receive the highest 3-star rating certification.

Visit the British Ceramic Confederation Delivering Net Zero for British Ceramics to discover more information regarding innovation in the sector.